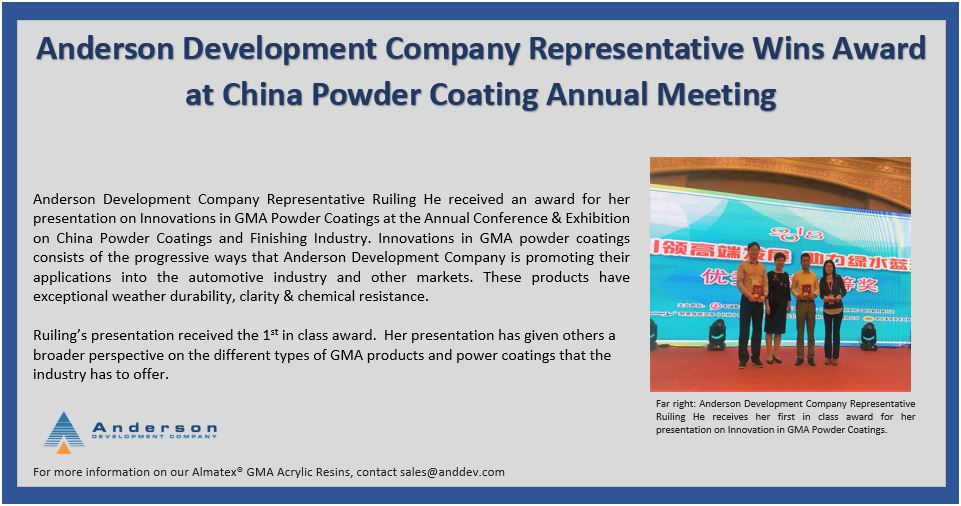

Anderson Development Company employee Ruiling demonstrates excellence in GMA Powder Coatings at the Annual Conference & Exhibition on China Powder Coatings and Finishing Industry.

Anderson Development Company employee Ruiling demonstrates excellence in GMA Powder Coatings at the Annual Conference & Exhibition on China Powder Coatings and Finishing Industry.

“Open Doors, Open Minds. Inspire the next generation of manufacturers.”

This is exactly what Anderson Development is doing when we open our doors to the students of Lenawee County. For the third year, Lenawee County participated in Manufacturing Day. This year, Anderson Development welcomed several students on October 4th for Manufacturing Day. The students were provided a tour of our R&D facilities, production plant, and had the opportunity to meet with many chemists and engineers. It is part of Anderson Development’s mission to help students learn about the many opportunities within manufacturing. By doing so, students can see how we apply what they learn in school, the various types of materials we produce and the types of potential career opportunities that are available to them within the chemical manufacturing industry.

Did you know?

•For every $1.00 spent in manufacturing, another $1.89 is added to the economy.

•In 2016, the average manufacturing worker in the United States earned $82,023 annually, including pay and benefits.

•Manufacturers have one of the highest percentages of workers who are eligible for health benefits provided by their employer.

•Over the next decade, nearly 3.5 million manufacturing jobs will likely be needed, and 2 million are expected to go unfilled due to the skills gap.

•Taken alone, manufacturing in the United States would be the ninth-largest economy in the world.

•Manufacturers in the United States perform more than three-quarters of all private-sector research and development (R&D) in the nation, driving more innovation than any other sector.

To view more facts about Manufacturing, visit https://www.mfgday.com/resources/20-top-facts-about-mfg

Anderson Development Company was eager to participate in the iChallengeU program through Michigan Works! Southeast again this year. This is Anderson Development Company’s fourth year of welcoming students into our facility and presenting them with a challenge to solve.

iChallengeU is a two week educational program, providing high school students the opportunity develop solutions to real world business problems. After the students have developed an answer to the given issue, they present a 10 minute pitch to a panel of 5 judges. The competition was hosted by Baker College in Jackson, Michigan on July 20, 2018.

This year, the students were tasked with the challenge of “How can Anderson Development make manual data entry, specifically expense reporting, more efficient?” The team representing Anderson Development Company, consisted of Lydia Lopez of Tecumseh High School, Destiny Smiddy, Mitchell, Sielsky and Keito Pifer, all Adrian High School. The students were led by educator April Platt of the Lenawee ISD. Jessica Vorhees, Accounting Associate, was the group’s primary contact from Anderson Development Company.

Over the course of the program, the students examined eight solutions. The team ultimately chose one solution to present to Anderson Development Company and for their presentation. The solution could save the company a significant amount of time and money. Overall, the team successfully eliminated a great deal of time in the data entry process and Anderson Development Company will most likely implement some of their ideas in the near future.

On behalf of Anderson Development Company and Wacker Chemical Corporation, we wish to extend our gratitude and thanks to all the county and city participants who took time on Saturday, May 12, 2018 to bring their household waste to Anderson’s Facility on E. Michigan Street for proper handling and disposal. Anderson has been providing this service to the community for many years. Despite the weather, residents and volunteer workers from Anderson and Wacker remained enthusiastic about making sure that hazardous materials from their homes and community were handled properly. In order to better provide this community service, Anderson and Wacker joined forces and offer the community the opportunity to bring unwanted materials to our respective sites for proper handling and disposal.

“Household materials can be an overlooked and misunderstood source of hazardous materials which could damage the environment. As part of the community, our companies are happy to help our neighbors by taking in these materials and making sure that they are disposed of properly to keep our community safe. We are proud of how we have been able to provide this service to the community each year and look forward to being able to help our community with this in the future. Proper disposal of these household waste materials not only prevents them from entering into our environment, it helps make our community a nicer place to live.”

-Mark Kramer, President & CEO of Anderson Development Company

“Wacker is pleased to collaborate with our partner Anderson Development Company by co-sponsoring the 21st Annual Household Hazardous Waste Collection Day.For the residents of Lenawee County, providing this service as a way to dispose of hazardous household waste in an environmentally responsible manner brings community and business together to achieve our common goal: protecting our natural resources. In conjunction with the Stubnitz Environmental Education Center, our community friends and families have the opportunity to also enjoy the great outdoors and experience Mother Nature at her best. I am truly impressed with each year’s turnout. Thanks to our volunteer employees for doing such a wonderful job of hosting and working the event. And to our community members, thank you for doing your part to help protect our environment.”

-David Wilhoit, President and CEO, Wacker Chemical Corporation

Nicole Collett, Anderson Environmental Manager reported that we collected materials including, flammable liquids, paints, propane, spray cans, fire extinguishers, products containing mercury, pesticides, acids, bases, batteries, fluorescent bulbs, and other materials. A total of 45,008 pounds of material was collected during this event.

This community-wide event coincided with two weeks of similar disposal opportunities of other materials sponsored by Lenawee County Solid Waste Coordinating Committee, the Lenawee County Solid Waste Department, Habitat for Humanity of Lenawee County, Cobalt Holdings, Greenjak, Dart Industries, and other valued supporting organizations. Anderson and Wacker also sponsored an event at the Stubnitz Environmental Education Center featuring free flowers for special contributors, nature walks, and an animal demonstration for children.

Thank you to all the Lenawee County Residents for bringing in their household waste, program sponsors and co-sponsors and especially all the employee volunteers who worked this event in making it such a huge success.

Mark Kramer

President & CEO

Anderson Development Company

David Wilhoit

President & CEO

Wacker Chemical Corporation

Anderson Development continues to expand our product offerings. Our newest product is AndurGel 00 50, a room temperature curable, plasticizer free system with many possible applications. Read more below:

Be sure to download AndurGel 00 50 Info Sheet for your own records.

Supporting students as they pursue STEM careers is critically important to Anderson Development Company and to the future of manufacturing in our area. In order to help students pursue their dreams, Anderson Development Company sponsors a number of scholarships for graduating seniors who are interested in pursuing science and technology degrees. The deadline for two of these scholarships are approaching, so if you are interested and meet the qualifications, please get your applications in. The scholarships are funded by Anderson Development, but the Lenawee County Educational Foundation (LCEF) administers them, so please submit your applications to LCEF by following the links below by February 28, 2018.

Overview

One Anderson Development Company – AHS Scholarship for $1000 will be awarded to a graduating senior from Adrian High School who plans to study chemistry or engineering.

Qualifications

• Applicant must be a graduating high school senior.

• Applicant must be graduating from Adrian High School in Lenawee County.

• Applicant must be applying for the scholarships through LCEF (link attached)

• Applicant must be planning to study chemistry or engineering.

Follow this link to apply:

ADC -Adrian High School Scholarship

Overview

The Anderson Development Company Scholarship was established in 1998. Two $1000 scholarships will be awarded to Lenawee County graduating seniors, who are pursuing a degree in Environmental Science.

Qualifications

• Applicant must be a graduating high school senior.

• Applicant must be graduating from a high school in Lenawee County.

• Applicant must apply for the College Scholarships through LCEF (link attached)

• Applicant must be pursuing a degree in Environmental Science.

Follow this link to apply:

Anderson Development Environmental Scholarship

Or for further information or to apply, contact:

Kristy Suiter

[email protected]

Assistant to the Director

Lenawee County Education Foundation

(517)265-1626

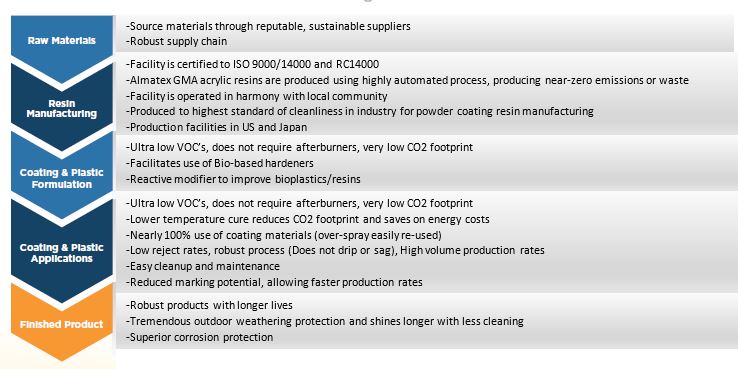

At Anderson Development Company, the protection of our local and global communities are critical to the long term success of our customers and to the long term success of our company. Anderson Development Company follows the principles of Responsible Care® which aims to continually improve performance related to the environment, health, safety, and security with a focus on our stakeholders.

Anderson Development Company is committed to the UNEP goals, focusing on the Triple Bottom Line. We recognize businesses must focus on the people and on the planet, not only for profit, because we cannot be successful in a world that fails.

The use of our Almatex® GMA acrylic resins in powder coating applications is well known to be environmentally and ecologically friendly, energy and economy saving, and provides excellent coating properties in finishing systems. Almatex® acrylic resins can also be used in bio-degradable plastics manufacturing.

Anderson Development Company is proud that Almatex® GMA acrylic resin promotes sustainability across the entire value chain.

Anderson Development Company is excited to welcome Jim Ressler to the Urethanes business as a Sales Specialist. He brings a wealth of industry knowledge from his years of work with mold release for urethane casting. Jim is a welcome addition as ADC strives to continue a long history of excellent technical and customer service. We asked Jim to share a little about himself as an introduction to the Anderson Development team, and this is what he had to say:

“I was born with an interest in how the world works and my passion is still learning new things and solving new problems. I worked as an auto mechanic while pursuing my BS in Chemistry at Millersville University. After school, I worked as a chromatography chemist at a local environmental laboratory. I became the go to person for instrument set-up and repair, installed the first computer network, and soon became technical manager.

I moved to Stoner Inc., a local award winning company, that had a core business selling mold release. There, I was able to work in customer service, then as an R&D Chemist, and finally in sales of mold release for polyurethane molding. Stoner offered a positive culture and was a recipient of the Malcolm Baldrige Award in 2003. It was an exciting day when the entire company traveled to Washington DC to receive the award from President George W Bush.

I moved to Stoner Inc., a local award winning company, that had a core business selling mold release. There, I was able to work in customer service, then as an R&D Chemist, and finally in sales of mold release for polyurethane molding. Stoner offered a positive culture and was a recipient of the Malcolm Baldrige Award in 2003. It was an exciting day when the entire company traveled to Washington DC to receive the award from President George W Bush.

My sales role at Stoner introduced me to the unique world of polyurethane. I was able to attend events and conferences such as CPI, U-Tech, PMA, Foam Expo and K-Show and learn about the fascinating world of polyurethane. These events and frequent visits with customers also introduced me to the collection of interesting people who process polyurethane. This is a unique collection of individuals who combine technical knowledge and business skills to put polyurethane to work.

I recently joined my longtime friends at Anderson Development in a sales role for polyurethanes. Anderson Development was attractive to me with its small company culture and big company resources. I look forward to getting even more involved in the technology of polyurethane elastomers and meeting more people. I hope that my mechanical and chemistry background, experience with mold release, and passion to help people will be a benefit to our customers.

Currently, my wife Janice and I live in Pennsylvania with two dogs and a cat. In our free time, we enjoy the outdoors and often go cycling, kayaking, hiking, backpacking and rock climbing. With any remaining free time, we are both pursuing second college degrees online. Travel is also a priority and we have been to most of the US States and several other countries. Finally, we love that we are grandparents and are having so much fun with our growing family.”

Manufacturing Day is a celebration of modern manufacturing. This day has inspired thousands of manufacturers to open their doors to show the public modern manufacturing in action and inspire the next generation of skilled workers. Manufacturing Day also gives companies an opportunity to tell the company’s story, dispel any outdated myths about manufacturing, and discover what else is being made in your community.

For the second year, Lenawee County participated in Manufacturing Day. This year, the number of students participating was approximately 400, nearly double that of last year! Each student participating in Manufacturing Day had the opportunity to talk with two local companies before enjoying a lunch with peers and industry representatives.

Anderson Development welcomed several students on October 5th for Manufacturing Day. The students were provided a tour of our R&D facilities as well as the production plant meeting many chemists and engineers. It is our mission to help students learn about the many opportunities within manufacturing so students can see how we apply what they learn in school, the types of materials we produce and the types of potential career opportunities are available to them within the chemical manufacturing industry.