Here at Anderson Development, our R&D teams are always looking to expand or improve our product lines. We aim to innovate and create products to meet our customer’s needs while making their products more competitive through ways such as improved processing or higher performance qualities. ADC has recently introduced two new Andur products denoted with “LQ,” meaning liquidity at room temperature. The liquidity offers advantages over some of the products that are a waxy solid at room temperature.

Andur LQ 9-5 APLF is a low free TDI polyester prepolymer which is a viscous liquid at room temperature. This provides an advantage over our other LFTDI polyesters which are a waxy solid at room temperature. This is helpful to processors because when initially heating the LQ 9-5 APLF, the material becomes flowable much faster, cutting time off from the preheat stage. The viscosity of the LQ 9-5 APLF is about 39000 cP at 86°F (30C°), and quickly drops to 6000 cP at 122°F (50°C). At processing temperatures, the prepolymer is well below 2000 cP and has a 5-6 minute potlife with Curene® 442 (MBOCA). Additionally, the Andur® LQ 9-5 APLF is also approvable for dry food contact per regulation 21CFR 177.1680.

Andur LQ 9-5 APLF is a low free TDI polyester prepolymer which is a viscous liquid at room temperature. This provides an advantage over our other LFTDI polyesters which are a waxy solid at room temperature. This is helpful to processors because when initially heating the LQ 9-5 APLF, the material becomes flowable much faster, cutting time off from the preheat stage. The viscosity of the LQ 9-5 APLF is about 39000 cP at 86°F (30C°), and quickly drops to 6000 cP at 122°F (50°C). At processing temperatures, the prepolymer is well below 2000 cP and has a 5-6 minute potlife with Curene® 442 (MBOCA). Additionally, the Andur® LQ 9-5 APLF is also approvable for dry food contact per regulation 21CFR 177.1680.

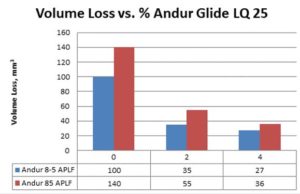

As a result of the research and testing for the technical paper ADC presented at PMA and CPI in 2019, we have introduced a new Andur® Glide product. Andur® Glide LQ 25 and is named as such due to its active ingredient content of 25% as well as its liquidity at ambient temperature. The Andur® Glide LQ 25 is an abrasion resistance additive consisting of a proprietary modified wax dispersed in a universal plasticizer. This makes it compatible in all urethane systems. The polymer/plasticizer mixture exhibits minimal separation over time, an advantage over Andur Glide 4830 which separates into two phases fairly quickly. Also, when pre-mixed with the prepolymer, no agglomerations or other undesirable mixing phenomenon occur. Below is a graph that shows the abrasion resistance benefit of using the Andur® Glide LQ 25 in Andur® 8-5 APLF and Andur® 85 APLF at levels of 2% and 4%. The data demonstrates that from 0 %to 2% the volume loss (ASTM 5963, rotary drum abrasion) is substantially reduced to about one-third of the control and at 4% there is another reduction of 25-35% from the 2% addition level. This translates to better sliding abrasion resistance in the final part. Andur® Glide LQ 25 is available in 5 gallon pails and 1 gallon cans, quart samples (~2 lbs.) upon request.